PRODUCTS

Manager Ren has strong design and manufacturing capabilities, quality assurance, stable supply, and excellent after-sales service

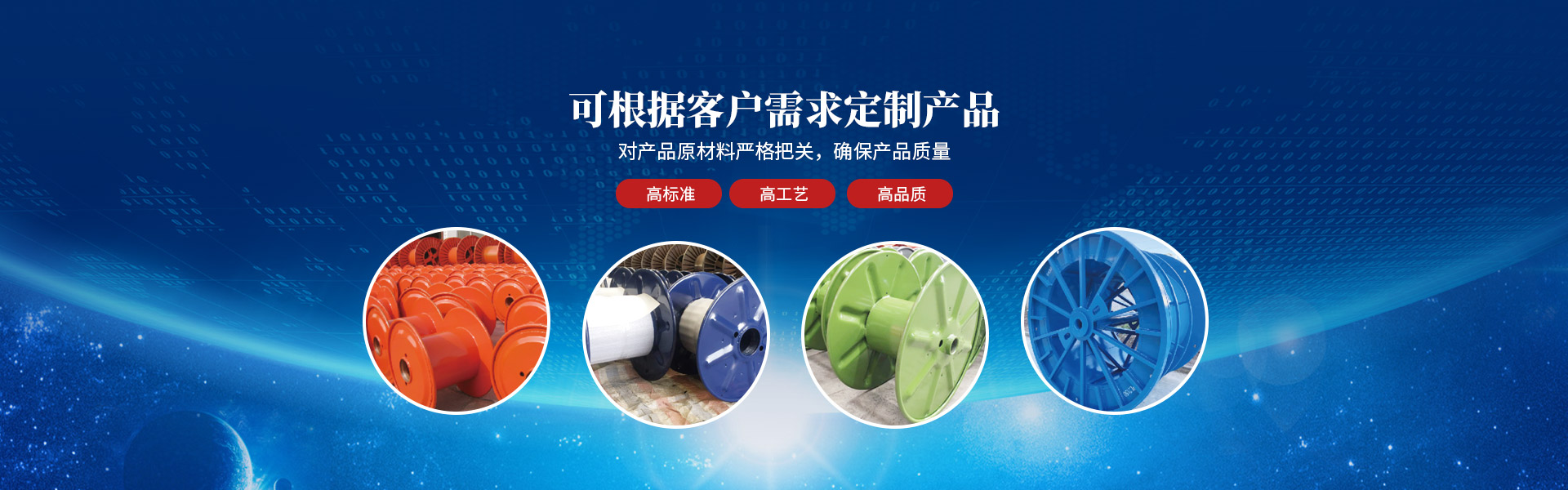

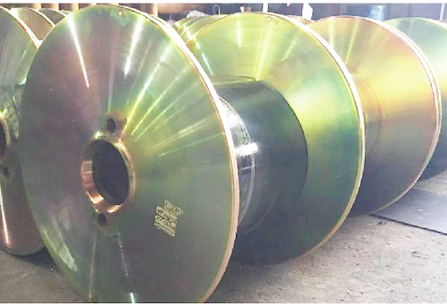

Manufacturer of specialized tools for wire and cable reels

Witness from over 100 industries and unanimous recognition from thousands of customers

ENVIRONMENT

Pay attention to every detail with care

COMPANY

Strong design and manufacturing capabilities, quality assurance, stable supply, and no excellent after-sales service

Yangzhou Tagore Electromechanical Technology Co., Ltd. is located in the Economic Development Zone of Yizheng City, Yangzhou City, Jiangsu Province. It is a professional manufacturer of I-beams and cable reels. The company has passed the ISO9001:2008 quality certification. We can also develop, design, and manufacture various non-standard products according to customer requirements. Our company's products are widely used in fields such as ultra-high voltage, medium low voltage, cross-linking, power cables, fiber optic cables, data communication cables, steel curtains, steel wire ropes, etc., and are highly favored by customers. The company adheres to the business philosophy of "sincerity and honesty, doing things for people", and wholeheartedly serves consumers.Welcome new and old customers to visit and guide!......

NEWS

Our ultimate goal is to achieve more stable product quality and customer satisfaction

What are the points to pay attention to when choosing a double-layer high-speed cable reel

2024-10-15

Application scenariosIndustrial production line: In industrial production, double-layer high-speed wire reels can efficiently wind and store wires, improving production efficiency.Household appliance maintenance: When repairing household appliances, the double-layer high-speed cable tray can conveniently store wires, avoiding wire entanglement and confusion.Construction: At the construction site, double-layer high-speed cable reels can help organize and store various wires and cables, improving construction efficiency.Energy saving lighting: In the field of energy-saving lighting, double-layer high-speed wire reels can ensure that wires are neatly wound, providing stable power support for energy-saving equipment such as LED lights.Radio station: In radio stations and other places, double-layer high-speed cable reels can organize and store a large number of cables to ensure the normal operation of radio equipment.Purchase suggestionsWhen choosing a double-layer high-speed cable reel, the following points should be noted:Reliable quality: Choose a double-layer high-speed cable reel with reliable quality and stable structure to ensure that it can maintain high work efficiency and stability during use.Wide applicability: Select suitable specifications and models of double-layer high-speed cable reels according to actual needs to ensure that they can meet the usage needs of different occasions.Easy to operate: Choose a double-layer high-speed reel that is easy to operate and user-friendly to improve work efficiency and reduce operational difficulty.In summary, double-layer high-speed wire reels are an efficient, convenient, and stable device for wire winding and storage, widely used in various fields. Attention should be paid to issues such as quality, applicability, and ease of operation when selecting and using.

What is the difference between double-layer high-speed cable reels and single-layer high-speed cable reels

2024-10-15

What is the difference between double-layer high-speed cable reels and single-layer high-speed cable reels? There are significant differences in structure, function, and application scenarios between double-layer high-speed cable reels and single-layer high-speed cable reels. Here are the main differences between them:1、 Structural differencesDouble layer high-speed wire reel: composed of two independently rotatable wire reels, which are located on different levels and can be used for winding and releasing wires separately. This design allows wires to be wound on two levels simultaneously, improving storage and release efficiency.Single layer high-speed cable reel: composed of only one wire reel, all wires are wound on the same layer. Although the structure is relatively simple, it may have lower efficiency when dealing with a large number of wires.2、 Functional differencesDouble layer high-speed wire reel: With two wire reels, more wires can be wound and stored simultaneously, improving work efficiency. At the same time, the two wire reels rotate independently without interfering with each other, ensuring the flatness and neatness of the wire winding.Single layer high-speed cable reel: Although it can also meet basic wire winding and storage needs, it may appear inadequate when dealing with a large number of wires. In addition, due to having only one wire reel, the speed of wire winding and release may be limited to some extent.3、 Differences in application scenariosDouble layer high-speed cable tray: Due to its high efficiency and convenience, it is widely used in situations that require fast and large-scale processing of wires. For example, industrial production lines, construction sites, radio stations, etc. In these situations, double-layer high-speed cable reels can significantly improve work efficiency and reduce labor costs.Single layer high-speed cable reel: suitable for occasions with relatively low wire usage and low efficiency requirements. For example, household appliance maintenance, small-scale engineering projects, etc. In these situations, single-layer high-speed reels are sufficient to meet the demand and have relatively low costs.4、 Other differencesStability and durability: Generally speaking, double-layer high-speed cable reels may have slightly better stability and durability than single-layer high-speed cable reels due to their more complex structure. But this is not absolute, it still needs to be judged based on factors such as the material and craftsmanship of the product.Cost: Due to its complex structure and diverse functions, the cost of double-layer high-speed cable trays is usually higher than that of single-layer high-speed cable trays. Therefore, when making a choice, it is necessary to weigh the actual needs and budget.In summary, there are significant differences in structure, function, and application scenarios between double-layer high-speed reels and single-layer high-speed reels. When making a choice, it is necessary to consider the actual needs comprehensively in order to select the most suitable product for oneself.